-

Q What is Gang-Nail timber connector?

A The GANG-NAIL Timber Connector System was introduced into New Zealand in the 1960’s. The system revolutionised house construction by prefabricating roof trusses, eliminating the need for expensive on-site “stick construction”.

-

Q What is the true strength of the Gang-Nail system?

A It is the technical support provided to Cangzhoufutong’s licensees which is the true strength of the Gang-Nail System. The Gang-Nail Truss System is based on the Gang-Nail timber connector which is a steel plate with multiple spikes or nails projecting from one face.

-

Q What is gang-nail Truss System?

A The Gang-Nail Truss System is based on the Gang-Nail timber connector which is a steel plate with multiple spikes or nails projecting from one face. The connectors are pressed into the surface of the timber using large hydraulic presses, causing the nails to embed in the timber.

-

Q What are nail-on plates?

A Cangzhoufutong Nail-on Plates are flat, galvanised or stainless steel plates which are nail-fixed to timber to form various types of joints. Their medium to high load capacities and wide range of sizes makes them ideally suited for on-site work

-

Q Do you need a mending plate on both sides?

A Generally, a mending plate is laid onto the surface of the area to be joined, repaired or strengthened and it is then screwed into place with four flat-head wood screws (more for the T-shape). For additional strength, plates are used on both sides of the connection.

-

Q How are nail plates installed?

A Hold the nail plate on the outside of the wall stud. This should be over the wiring hole. Nail in the spikes that attach the top and bottom of the nail plate into the stud. To continue the protection onto the other side of the stud, install another nail plate as you did the first one.

-

Q Are nail plates required for electrical wiring?

A It only applies to cables passing through a hole in the member. It sounds like in your case, the cables are run on top of the purlins, so technically, you do not need nail plates there.

-

Q How thick do nail plates need to be?

A Plastic and copper piping penetrating framing members to within 1 inch (25.4 mm) of the exposed framing shall be protected by steel nail plates not less than No. 18 gauge (0.0478 inches) (1.2 mm) in thickness.

-

Q What is a mending plate?

A A mending plate is a metal connector that is used to repair or strengthen joints in wooden furniture, picture frames, shelving and for many other household connections. Mending plates are available in straight, T-shaped, flat L-shaped and bent L-shaped designs.

-

Q What are nailing plates used for?

A Nail plates are flat strips of galvanised steel which have been punched to create multiple small prongs on one side. These are hammered into the surface of adjacent pieces of timber to hold them together. They are widely used in framed structures and in the prefabrication of structural elements such as trusses.

-

Q Where are nailing plates required?

A When Building Or Renovating, Building Code Requires Nail Guard Plates Be Installed Where Water Pipes Run Through Or Near Wall Studs. Today’s International Plumbing Code States: “Protection against physical damage.

-

Q What is a Tylok plate?

A Tylok Plate is designed for on-site use and can readily be applied by hammer as well as hydraulic press. Tylok Plates are suitable for a wide range of applications such as trusses, formwork, site splicing, etc. Tylok Plates are manufactured from galvanised steel in a range of sizes.

-

Q What is a gang nail plate?

A A truss connector plate, or gang plate, is a kind of tie. Truss plates are light gauge metal plates used to connect prefabricated light frame wood trusses. They are also known as stud ties, metal connector plates, mending plates, or nail plates.

-

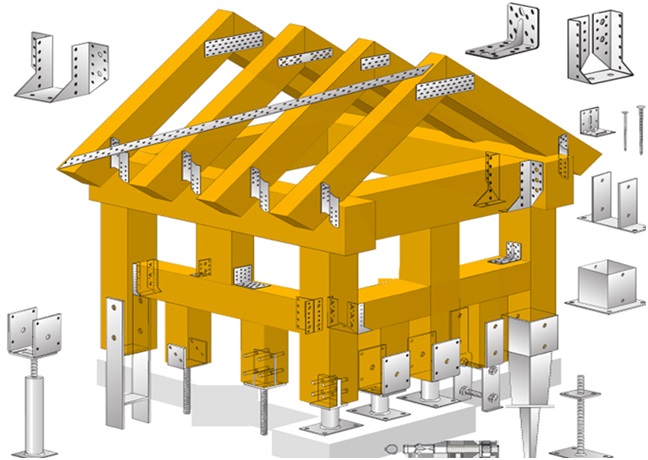

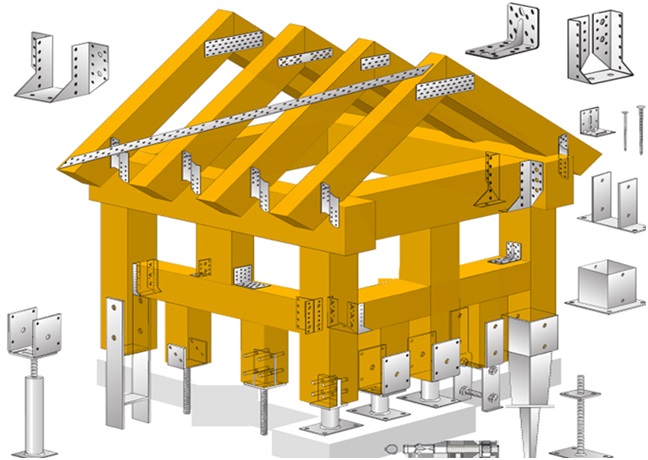

Q When framing a house, why is it better to use connectors than the historic practice of toe-nailing?

A Framing materials held together with structural connectors can withstand much stronger forces than if held together with nails. Connectors have what is called a higher load capacity than nails (see example below). In a high wind storm, for example, nails are much more likely to pull apart or pop out than a metal connector. A connection made with a metal connector can be pulled apart, but it takes much greater force to separate it than a simple toe-nailed connection. A home built with connectors is better able to resist forces from high winds and earthquakes.

-

Q What is a continuous load path and why is it important for a home?

A A continuous load path is a method of construction that uses a system of wood, metal connectors, fasteners (like nails and screws) and shearwalls to connect the structural frame of the house together. It ties the house together from the roof to the foundation. A continuous load path is important because it helps redistribute outside pressures or forces caused by earthquakes and high winds, transferring these external forces from the frame to the foundation, which is securely anchored into the ground. A home with a continuous load path is much better equipped to withstand the strong forces caused by high winds, tornadoes, hurricanes and earthquakes.

-

Q What is a shear-wall?

A Shear-walls are reinforced walls within a home that have been engineered to help resist the shear (racking) forces that are caused by high winds or lateral forces that are caused by earthquakes. Shear-walls are typically constructed by attaching wood sheathing and holdown connectors to a section of the wood framing along a wall. Pre-manufactured shear-walls are frequently used in homes as they come pre-assembled and ready for installation.

-

Q What is a fastener?

A Fasteners typically refer to nails, screws, bolts or anchors. Fasteners are used with connectors to attach framing materials together, such as wood, masonry and concrete.

-

Q What is a wood connector?

A Structural connectors are made out of steel, and are engineered to connect and strengthen the frame of a home. Reinforcing the frame of a home with structural connectors helps the home resist damage caused by earthquakes, high winds and hurricanes. Framing materials secured with connectors are much stronger than if secured only with nails (called toe-nailing).

Connectors come in all shapes and sizes, and have a variety of names, such as joist hangers, holdowns and hurricane ties. Homeowners don't typically see connectors in their homes because they are covered up behind the walls.

-

Q Can you make the complete set of wooden construction fittings?

A Of course, we can produce a full set of wooden construction metal fittings, If I have the chance, I'd like to invite you to visit our production workshop and samples.

-

Q How many years has your factory been in the field of wooden building fittings? How about the machines and equipment?

A We have been in this field for 13 years, and we have 5 engineers, 10 technicians, and 120 employees; We have a variety of stamping machine equipment, punch tons of a variety of types, can meet the needs of customers;This year we have expanded the new plant and the building. The building has been put into use and the construction area has reached 7000 square meters, We warmly welcome you to visit our factory and establish a cooperative relationship with you.