-

Q Can you use just 4 corners for a 5 ft. x 10 ft. long bed?

A We did a 4x8 ft bed, but put a 2x12 in the middle for added support. I think you can do it, but would put a support piece in the middle so it won't bow out (presuming you are making a garden bed & filling it with dirt.

-

Q can I use this for 1" thickness wood?

A Best if used on 2” wood stock.

-

Q Garden Bed Corner Bracket - Set of Four - 20-24 Inch Bed

A Question:Do you have a vesion with more holes for 2x6 lumber? (4 boards high) What gage is the steel?

Answer:Yes,we have

Question:Any rusting potential with these?

Answer:the guaranty time is 5 years

Question:What are the size of the screw holes?

Answer:Don't worry,the screws came with the brackets.

Question:are there matching flat side brackets, to keep 10 ft lengths of 3 stacked 2x6s from bowing? Or not needed?

Answer:It is unnecessary for flat side brackets

-

Q Set of 4 Raised Garden Bed Corner Brackets for 10"-12" Bed

A Question:are these for true 2" boards, or Milled 2" boards (which are actually 1 1/2 inch) ?

Answer:Milled - 1 1/2”

Question:Would I be able to adjust the angles on these? Trying to build hexagon beds, so the angles would not be 90...

Answer:No, they are quite stout and at 90 deg.But we can do the hexagon brackets if you have a design drawing

Question:Are these black or more brownish in color?

Answer:They are a bronze-brown, not black.

-

Q Garden Bed Corner Bracket - Set of Four - 10-15 Inch Bed

A Question:Can these be placed on the inside of the boards so they do not show?

Answer:Yes

Question:who would not want radius corners on a bed?

Answer:This is meant for vegetable/flower raised bed construction outdoors with treated lumber as tha sides. The squared brackets connect the squared off lumber sides. A radius finish would add un necessary cost.

But we also could do the brackets if you supply a design drawing a sample to us.

Question:Are these garden brackets rust proof? I don't want them falling apart in a couple of years.

Answer:Yes,the surface is finished with powder coating to anti rust.

Question:How thick is this hot rolled steel material?

Answer:These are made from 14 gauge HR.

-

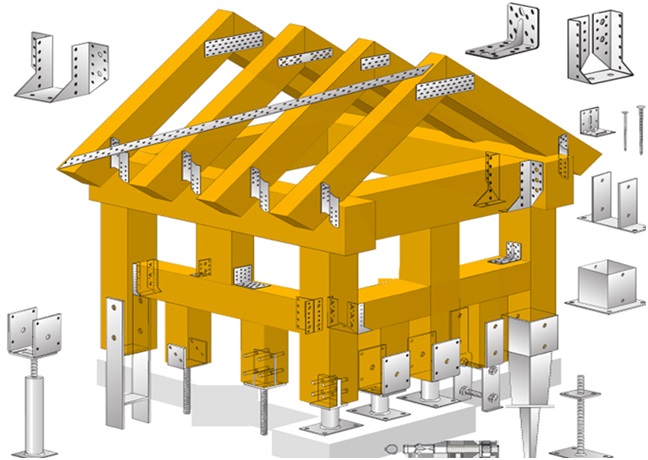

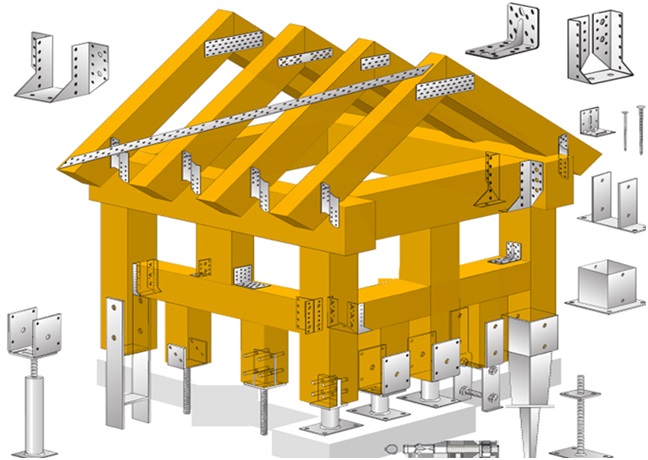

Q When framing a house, why is it better to use connectors than the historic practice of toe-nailing?

A Framing materials held together with structural connectors can withstand much stronger forces than if held together with nails. Connectors have what is called a higher load capacity than nails (see example below). In a high wind storm, for example, nails are much more likely to pull apart or pop out than a metal connector. A connection made with a metal connector can be pulled apart, but it takes much greater force to separate it than a simple toe-nailed connection. A home built with connectors is better able to resist forces from high winds and earthquakes.

-

Q What is a continuous load path and why is it important for a home?

A A continuous load path is a method of construction that uses a system of wood, metal connectors, fasteners (like nails and screws) and shearwalls to connect the structural frame of the house together. It ties the house together from the roof to the foundation. A continuous load path is important because it helps redistribute outside pressures or forces caused by earthquakes and high winds, transferring these external forces from the frame to the foundation, which is securely anchored into the ground. A home with a continuous load path is much better equipped to withstand the strong forces caused by high winds, tornadoes, hurricanes and earthquakes.

-

Q What is a shear-wall?

A Shear-walls are reinforced walls within a home that have been engineered to help resist the shear (racking) forces that are caused by high winds or lateral forces that are caused by earthquakes. Shear-walls are typically constructed by attaching wood sheathing and holdown connectors to a section of the wood framing along a wall. Pre-manufactured shear-walls are frequently used in homes as they come pre-assembled and ready for installation.

-

Q What is a fastener?

A Fasteners typically refer to nails, screws, bolts or anchors. Fasteners are used with connectors to attach framing materials together, such as wood, masonry and concrete.

-

Q What is a wood connector?

A Structural connectors are made out of steel, and are engineered to connect and strengthen the frame of a home. Reinforcing the frame of a home with structural connectors helps the home resist damage caused by earthquakes, high winds and hurricanes. Framing materials secured with connectors are much stronger than if secured only with nails (called toe-nailing).

Connectors come in all shapes and sizes, and have a variety of names, such as joist hangers, holdowns and hurricane ties. Homeowners don't typically see connectors in their homes because they are covered up behind the walls.

-

Q Can you make the complete set of wooden construction fittings?

A Of course, we can produce a full set of wooden construction metal fittings, If I have the chance, I'd like to invite you to visit our production workshop and samples.

-

Q How many years has your factory been in the field of wooden building fittings? How about the machines and equipment?

A We have been in this field for 13 years, and we have 5 engineers, 10 technicians, and 120 employees; We have a variety of stamping machine equipment, punch tons of a variety of types, can meet the needs of customers;This year we have expanded the new plant and the building. The building has been put into use and the construction area has reached 7000 square meters, We warmly welcome you to visit our factory and establish a cooperative relationship with you.

-

Q For timber connector,what's the thickness of your product?

A In general, in addition to the larger load bearing products, other products, such as Nail plate, Joist hanger and bent plate connections, are likely to be in thickness of 1 mm, 2 mm, 2.5 mm and 3 mm. Because we are factories, we provide customized service to our customers. We can do the production according to the customers' reasonable requirements.

-

Q For your timber connector, what material will be used?

A Our commonly used materials are DX51D-Z275 galvanized sheet, SGC340-z275 galvanized sheet (equivalent to G300-Z275 galvanized sheet) and stainless steel ss316. (Accept custom material service and purchase materials according to customer's requirement.)

-

Q Do you have design capabilities?

A Yes, we would be delighted to help in the design of your parts. Please contact us as early as possible in the design process.

-

Q Do you do any processing in your facility?

A We will do all secondary processes in house (drilling, tapping, machining etc.) We do not provide any heat treating, plating or finish processing in house.

-

Q For metal stamping parts,what is your normal lead time?

A 3 to 7 working days for samples,and bulk production based on your quantity

Our normal lead time for reorders is 3-4 weeks. Orders requiring tooling can be 5-10 weeks depending on how complex the part is.

-

Q How much does the tooling cost?

A We refer to the tooling charge as a NREC (Non-Recurring Engineering Charge). For a simple flat part with round holes about 2in x 4in, we would charge about $250.00. As the parts become more complex, the NREC gets higher, but is still the most economical way to build tooling that will last for the life of the job.

-

Q What about metal stamping part quality?

A Our methods of tooling will produce the same or better quality than all other methods of fabrication.

-

Q How many parts will this tooling produce?

A Our short run tooling is guaranteed for the life of the job. You never have to pay for repair or maintenance.